A firm favorite with professionals for their warehouses, storage facilities and industrial buildings, sheet metal roofs are highly economical, making it possible to fit out a building at lower cost. However, they are not without their faults. Indeed, their thinness and lack of insulation result in very poor thermal performance. At a time when energy conservation is more important than ever, good insulation is essential. With this in mind, it is possible to improve the performance of sheet metal roofs with expanding foam or thermal insulation paint.

Methods for insulating tin roofs

Roof insulation is a major factor in energy efficiency. Indeed, it is estimated that almost 30% of a building's energy losses come from the roof. This figure is even higher for sheet metal roofs. With its very low thickness and lack of protection, sheet metal roofing provides protection from the elements.

For professionals committed to a responsible approach or wishing to limit their energy bills, it becomes essential to insulate these roofs. This raises the question of insulation methods.

Generally speaking, when a roofing or insulation professional intervenes, he or she can choose between a cold roof or a warm roof method. In the case of sheet metal roofs, he will be obliged to adopt the warm roof option. This term refers to insulation applied directly to the roof, with no ventilated space between the metal sheet and the chosen insulation.

A second constraint is the difficulty of building solid infrastructure under the sheet metal or steel roof. Ultimately, only two viable solutions remain.

Expanding foam

The first way to insulate a sheet metal roof is with expanding foam. This polyurethane foam is very easy to use. It often comes in aerosol form, and all you have to do is spray it under the target roof, and the insulation will start working on its own. In fact, polyurethane expanding foam has a very interesting feature: it is capable of adapting itself to the target environment to fit its shape.

This solution is economical, both in terms of labor and initial purchase cost. However, the visual effect is not particularly aesthetic. This can be improved by using wood panels applied under the insulation to mask the whole.

Insulating paint

Professionals know all too well: in summer, warehouse temperatures can be unbearably high. The other solution for insulating a tin roof is insulating paint. This method is highly recommended as a complement to the installation of polyurethane foam.

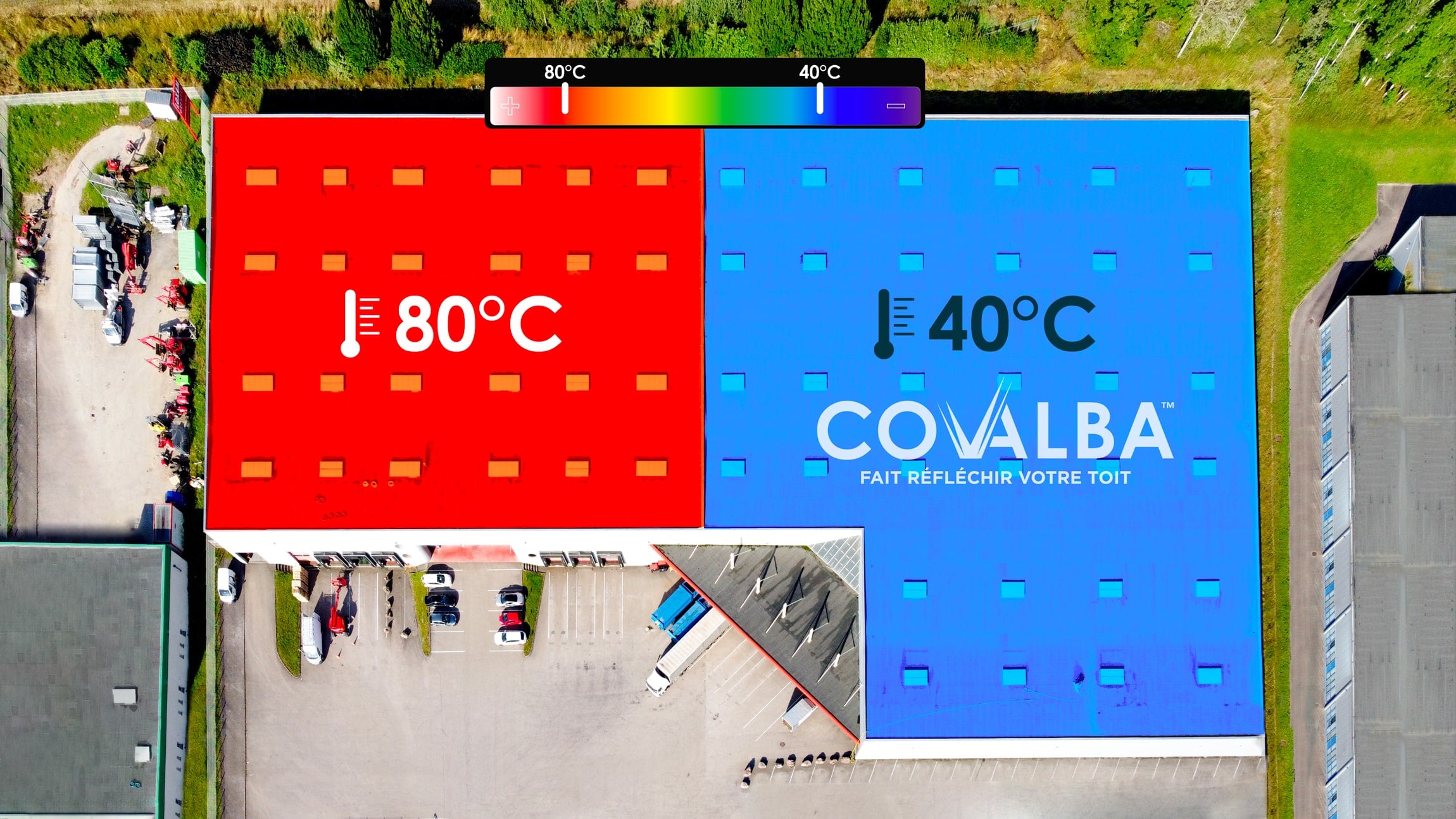

Insulating paint is applied to the outer surface of the roof by a professional trained in these products and their application. This white roof coating can reflect up to 94% of the sun's rays back into the atmosphere, thus blocking the heat reaching the roof. As a result, the roof does not accumulate heat, and the repercussions inside the building are greatly reduced: the temperature at the roof surface can be halved (from 80°C to 40°C), and up to 10 degrees can be saved inside the building.

Thanks to the low initial purchase cost of expanding foam, it's possible to invest additionally in the application of anti-heat paint for thermal insulation.

💡 A ll our advice on how to insulate your roof properly

Problems associated with sheet metal roof insulation

With these two methods, effective insulation can be achieved. However, there are two issues to consider. Firstly, rainwater must be drained off properly to avoid damaging the interior insulation. To this end, gutters can be installed all around the roof surface to drain off the water.

One of the major risks of insulating tin roofs is condensation. In winter, when warm indoor air rises to drain through the roof, condensation can form on the roof in contact with cold outdoor air. The use of insulating paint on the outside can help protect against this problem. Indeed, tin roof paint has properties that guarantee the absence of condensation.

To find out more :